weber.fug 877

Product formerly named: CERINOL Flex

Water-repellent multi-use grout for all common wall and floor tiles with joint width 2 - 20 mm

Colours:

anthracite, cement grey, medium grey, silver grey

Water demand:

approx. 2.8 - 3.1 liters /15 kg

Storage:

The product can be stored at least 6 months (paper bag) and at least 9 months (plastified bag) in its original unopened packaging, if kept dry and protected from moisture

Fields of application

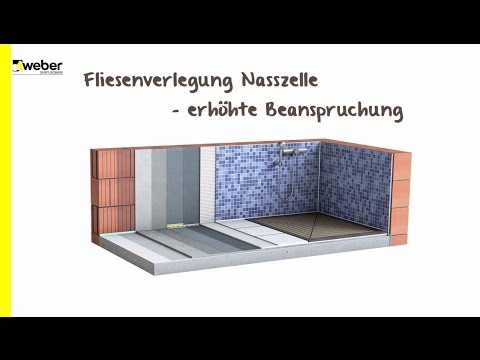

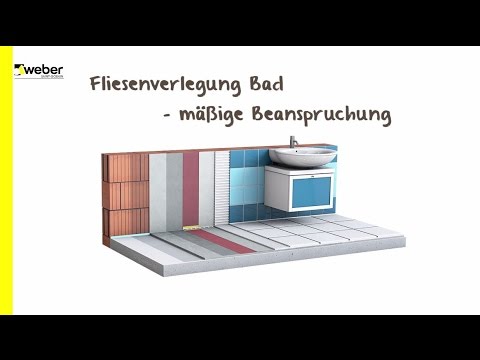

weber.fug 877 is used as multi-use and flexible grout for use indoors and outdoors, in damp areas, wet-duty areas, (shower facilities, balconies/terraces), areas permanently underwater (water tanks, fountains etc.) and heated screeds. For following coverings: wall and floor ceramic tiles, mosaic, stoneware brick slips, porcelain stoneware, stoneware, earthenware, split tiles and deformation-resistant artificial stone slabs. For use indoors and outdoors.

Main features

- EMICODE EC 1PLUS: very low emission of volatile substances

- class CG 2 WA: CG: cement-based grout – 2 WA: low water absorption (W) and high abrasion resistance (A)

- certified by Det Norske Veritas for use on American cruise ships

- for narrow and wide joints (width 2 - 20 mm)

- quickly open to pedestrian traffic

- excellent adhesion to joint sides

- watertight

- resistant to frost and thaw cycling

- high filling grade

General notes

- Limits of use: do not use weber.fug 877 for grouting natural stones, resin-bound artificial slabs (“engineered stones”) and materials with sensitive surface; in these cases, use the ceramic and natural stone grout with crystal effect weber.fug 875 F. Follow the supplier’s recommendations; if in doubt, carry out a test on a trial area.

- weber.fug 877 can be used in areas permanently underwater such as water tanks, fountains etc., but not in drinking water tanks and swimming pools; in these cases, use the high-strength cement-based grout weber.fug 873or the epoxy resin binder mixed with sand weber.fug 878.

- All characteristics mentioned in this data sheet are based on a temperature of +23 °C without draught and a relative humidity rate of 50%.

- High temperatures and low humidity rates accelerate, low temperatures and high humidity rates delay the setting process.

- Substrates with different porosity, type of material to be laid and joint sides can lead to colour differences once the grout has completely set.

- Mortar residues can accumulate on tiles with microporous (for ex. Lappato), porous, textured (rough) or matt glazed surfaces; if in doubt, carry out a test on a trial area to ascertain if discoloration is likely. If necessary, pre-wet the surfaces in order to prevent discoloration.

- Corner joints, connection joints to installed components and pipe ducts must be closed with an elastomeric silicone-based joint sealant, like weber.fug 880, 881 or 883 in accordance with the job site requirements.

- The type and appearance of material to be laid might have an influence on the final colouring of the grout; if necessary, carry out a test on a trial area.

- Do not use material that has already stiffened.

Special notes

- Do not use highly-acid cleaning agents or high-pressure/steam jet cleaners on the grouted surfaces.

- Wait for 14 days before using conventional household cleaners.

- In outdoor areas discoloration, washout and efflorescence due to environmental factors cannot be ruled out.

- In case of use in permanently immersed areas, a corrosion on the cement-based grout should be anticipated if the water is too soft. Therefore, the water must contain a minimum content of calcium carbonate per liter (hardness scale – in Germany scale of 5° - 20°). Comply with the national standards and/or guidelines relating to the grade of local water hardness; if not issued, request technical advice.

- A declaration of conformity for marine applications can be found under: https://www.de.weber/webermarine-produkte.